Forming & Molding

Cold Forming

Your industry, especially if you’re in transportation or healthcare, may demand exacting specifications, which often introduces complex curvatures. Cold form capabilities often offer the right solution to mold and create products that hold the right shape to meet challenging specifications.

The unique engineered cellular structure of IMPAXX™ means materials can be processed quickly and cost effectively, using no heat to introduce unique shapes to match complex curvature.

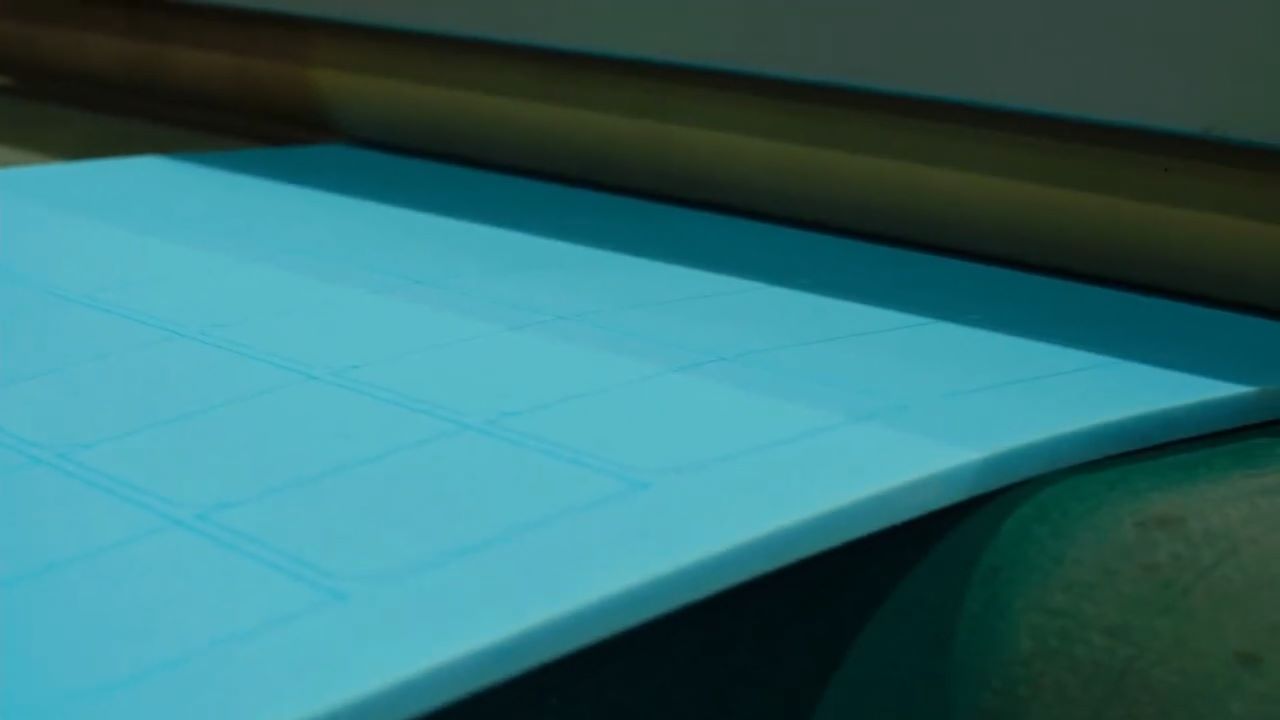

Vacuum Forming

Vacuum forming (AKA vacform or thermoform) capabilities allow for rapid development of components including:

- Overmolded IMPAXX™ components for enhanced assembly and NVH characteristics

- Forming of composites for structural applications

- Encapsulation of final products for protective packaging

- Interior trim panels and liners

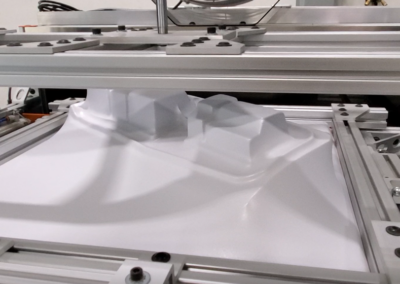

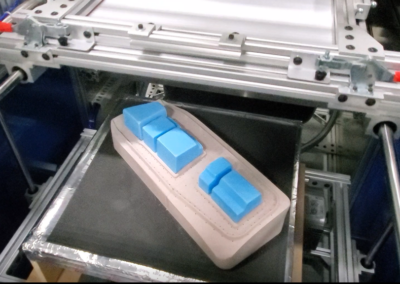

Vacform Tooling with 3D Printing

Coastal Automotive utilizes a large format 3D Printer to engineer and manufacture the Vacform tooling to the customers requirements.

Die Cutting

Our die cutting capabilities offer you versatility, affordability and customization options when CNC or other forming techniques are not a good fit for your part’s shape or material.

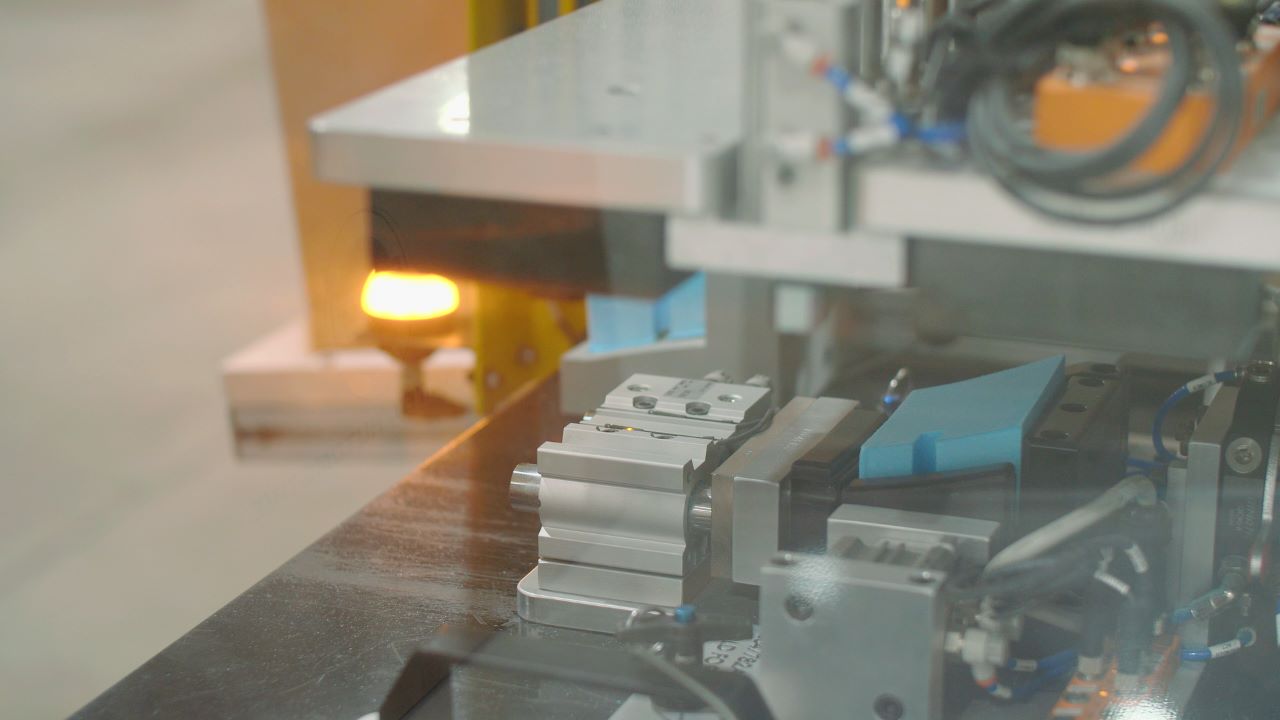

Compression Molding

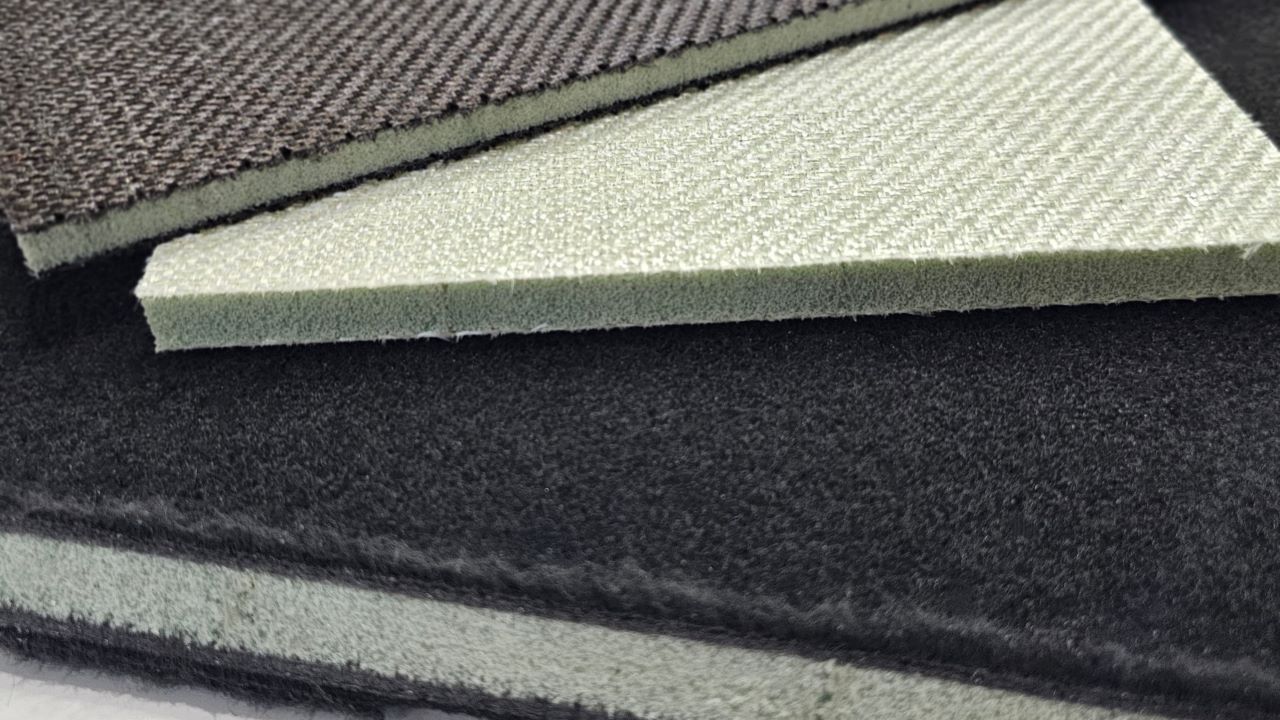

Our customers are looking for innovative, light-weight composite solutions for many durable and structural applications. Compression molding technology lets us shape sophisticated components using multiple materials as the cores and skins to tailor performance based on their requirements.

- Ability to mold singular or multi-layer materials

- Variable thickness components with complex shapes

- Low cost process with the capability of high volume production

- Works with a variety of materials.

Let’s Get Started

Contact us to learn more.