Solutions

Already known as the premier supplier of passive safety and energy management solutions in the automotive industry, Coastal Automotive offers numerous advanced materials and manufacturing capabilities that can improve cost savings, quality and efficiency of your products.

Capabilities

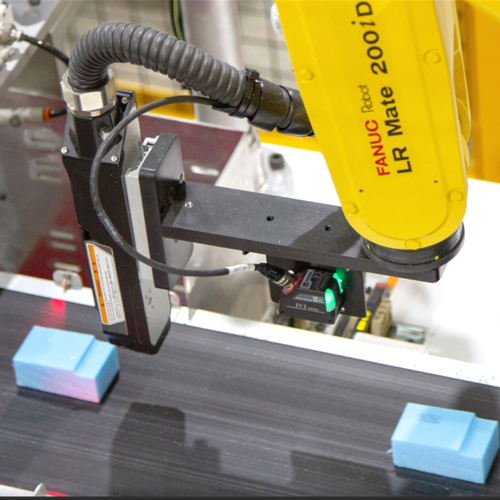

CNC Wire Cutting

Precision, computer-controlled foam cutting for 2D and 3D applications.

Forming & Molding

Our forming and molding capabilities include die cutting, vacuum and cold forming, and compression molding.

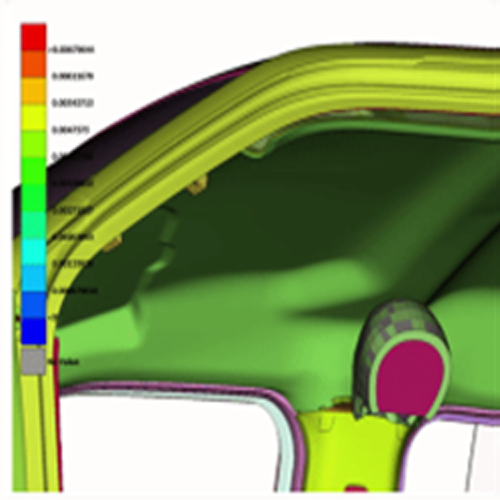

Computer-Aided Engineering

CAE services that improve product designs, reduce development cost and time, increase safety ratings and compliance.

Assembly

Enhance your designs or implement new materials without expanding your assembly operations.

Product Development

Customer-centric implementation of agile processes and capabilities to facilitate quick yet precise turnaround.

motorsports Safety

We’re NASCAR’s premier energy management provider with our IMPAXX™ energy management foam.

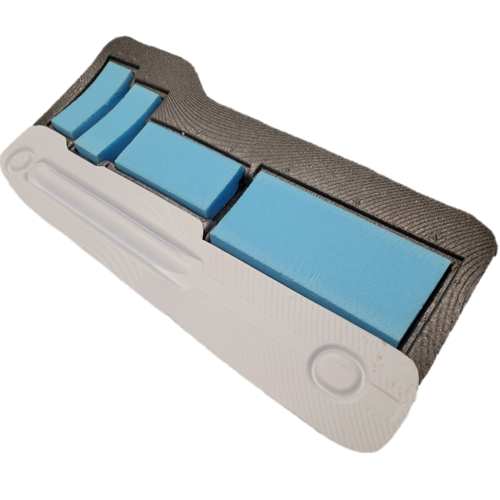

Additive Manufacturing

Application of 3D technology for large volumes of customized parts on demand.

Materials

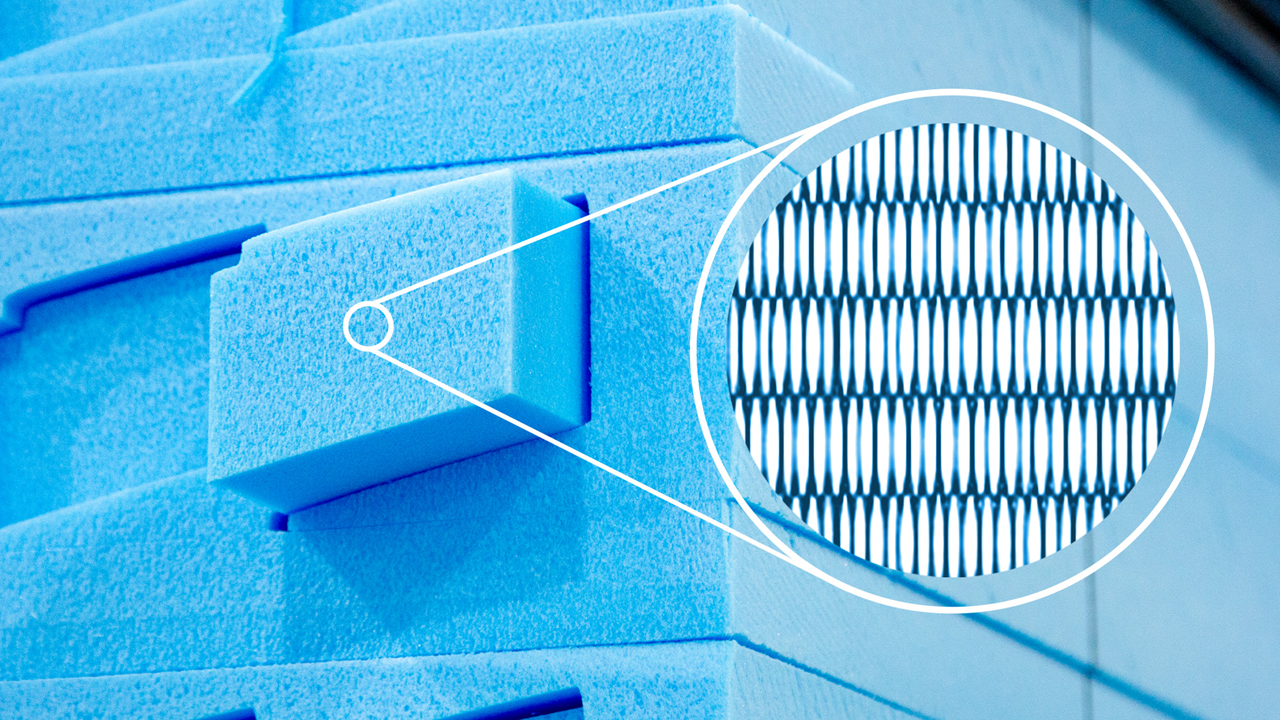

IMPAXX™

IMPAXX™ foam is the most efficient energy management material available to the automotive industry today. Our customers have deployed IMPAXX™ components in automotive headliners, bumpers, seating and headrests in order to maximize passenger safety while decreasing product weight by as much as 91% when compared to competing materials.

SDR Utility Foam

Support/Deflect/Rebound utility foam is a multi-use, microcellular polyethylene foam designed for a variety of applications. Providing a reaction surface engineered specifically for rapid deployment, SDR Utility Foam’s unique cellular structure provides responsive loading and reliable performance.