IMPAXX™

Stable & Consistent Energy Absorbing Foam

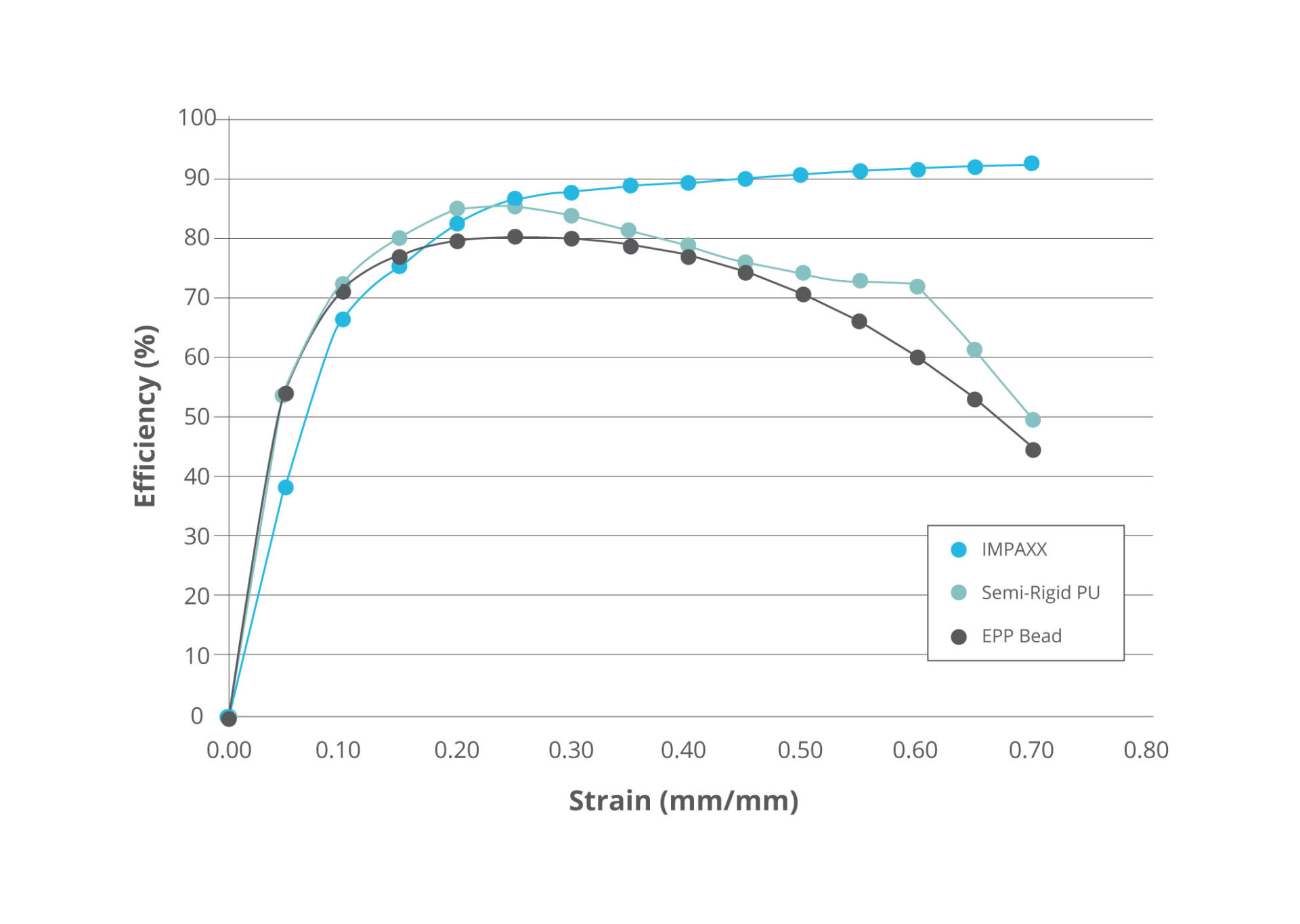

IMPAXX™ is the most efficient and effective energy management material in the automotive industry today. The energy absorption performance of IMPAXX™ across applications, combined with its significantly lighter weight and precision cutting standards makes it the premier energy-management solution for the automotive industry.

%

Potential Weight Savings

Lose Weight & Increase Passenger Safety

With each year, standards and concerns for passenger safety grow, and Coastal Automotive provides the solutions you need to stay in step with that growth. IMPAXX™ provides the highest possible efficiency among energy absorption (EA) countermeasures, significantly outperforming its peers in the industry in terms of weight-to-performance ratios by as much as 91%. This becomes especially important as weight-reduction is directly related to improving EV range in a competitive market.

Compliance & Standards

Customers rely on IMPAXX™ to meet demanding compliance requirements, including those from the National Highway Traffic Safety Administration (NHTSA) and United Nations Economic Commission for Europe (UNECE). And we’re constantly working to develop the most innovative solutions to ever-changing energy management needs.

Applications

You’ll find IMPAXX™ products in the headliners, doors, headrests and instrument panels for hundreds of the world’s top-selling cars and trucks. Applications include (but aren’t limited to):

- Headliners and pillar trims as head-impact countermeasures

- Lower interior front and rear-door side-impact countermeasures

- Steering columns and instrument panels

- Under-carpet energy management systems

- Bumper and seating systems

Choose IMPAXX™ for

$0 Tooling Expenses

Lower costs of development and capital investment on tooling

Precision Cutting

CNC wire cutting for tight tolerances and exact standards

Lower Weight

Up to 91% lower weight than competitors

Lower Packing Space

Make room for improved passenger comfort

Meeting Standards

Lower weight helps meet Corporate Average Fuel Economy and CO² standards

Consistent performance

From prototype to production & at a complete range of operating temps

Improved performance

Outperforms EPP bead foams, PU foams, and thermoformed plastic parts

Fast Cycle Times & Flexibility

No tooling means you go from concept to production in days.

Multiple Assembly Methods

Including advanced nest, pressure sensitive adhesive & mechanical attachment

Trusted by NASCAR

IMPAXX™ is the trusted energy-absorption material of NASCAR for driver safety. Learn more about how NASCAR uses IMPAXX™ in vehicles as attenuators (entrance to pit row) to protect drivers.

Sustainable & Recyclable

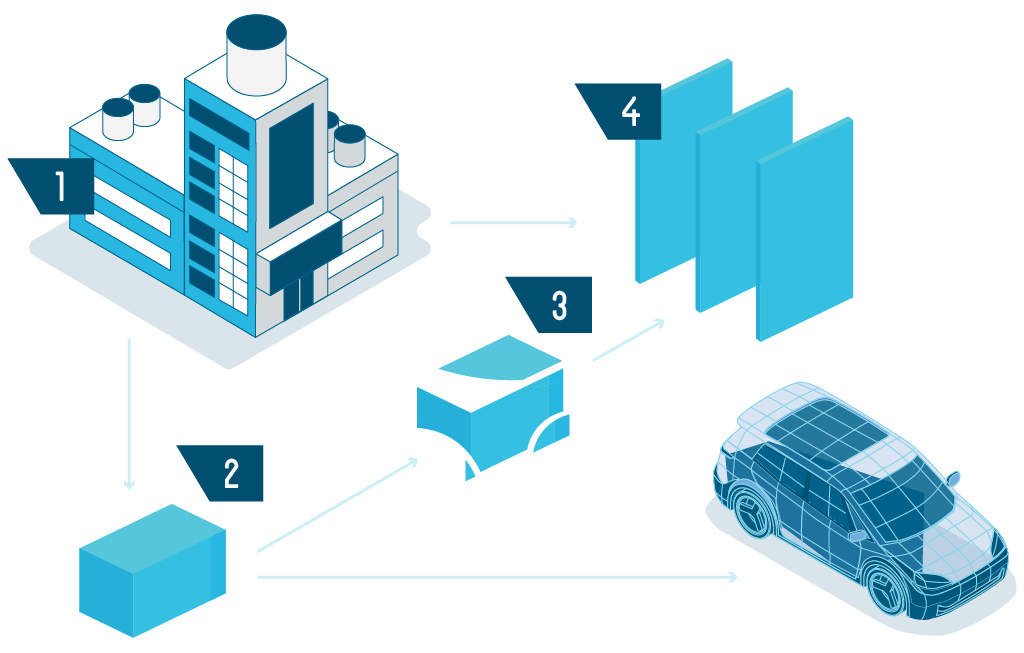

Since our founding, we’ve made sustainability a central focus of our manufacturing processes. IMPAXX™ is a highly engineered extruded polystyrene (XPS) foam, which can be recycled for several different applications.

- Material suppliers manufacture IMPAXX™ foam for Coastal Automotive.

- Coastal Automotive utilizes IMPAXX™ to manufacture energy management solutions.

- 100% of unusable foam or scrap from our manufacturing process is collected and shipped to our recycling partners.

- Our recycling partners use the recycled material to make other polystyrene-based products.

CAE Resources & Specs

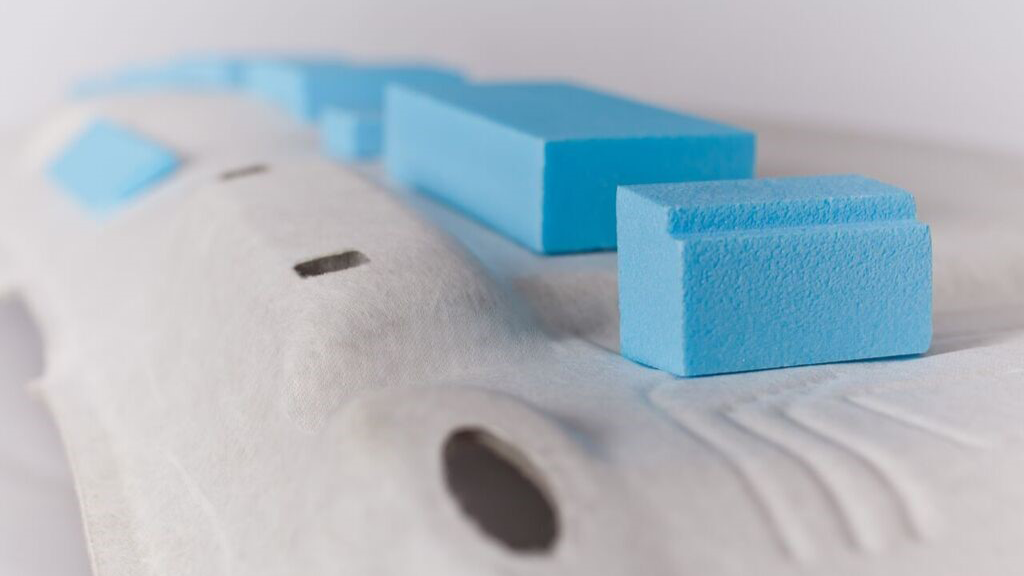

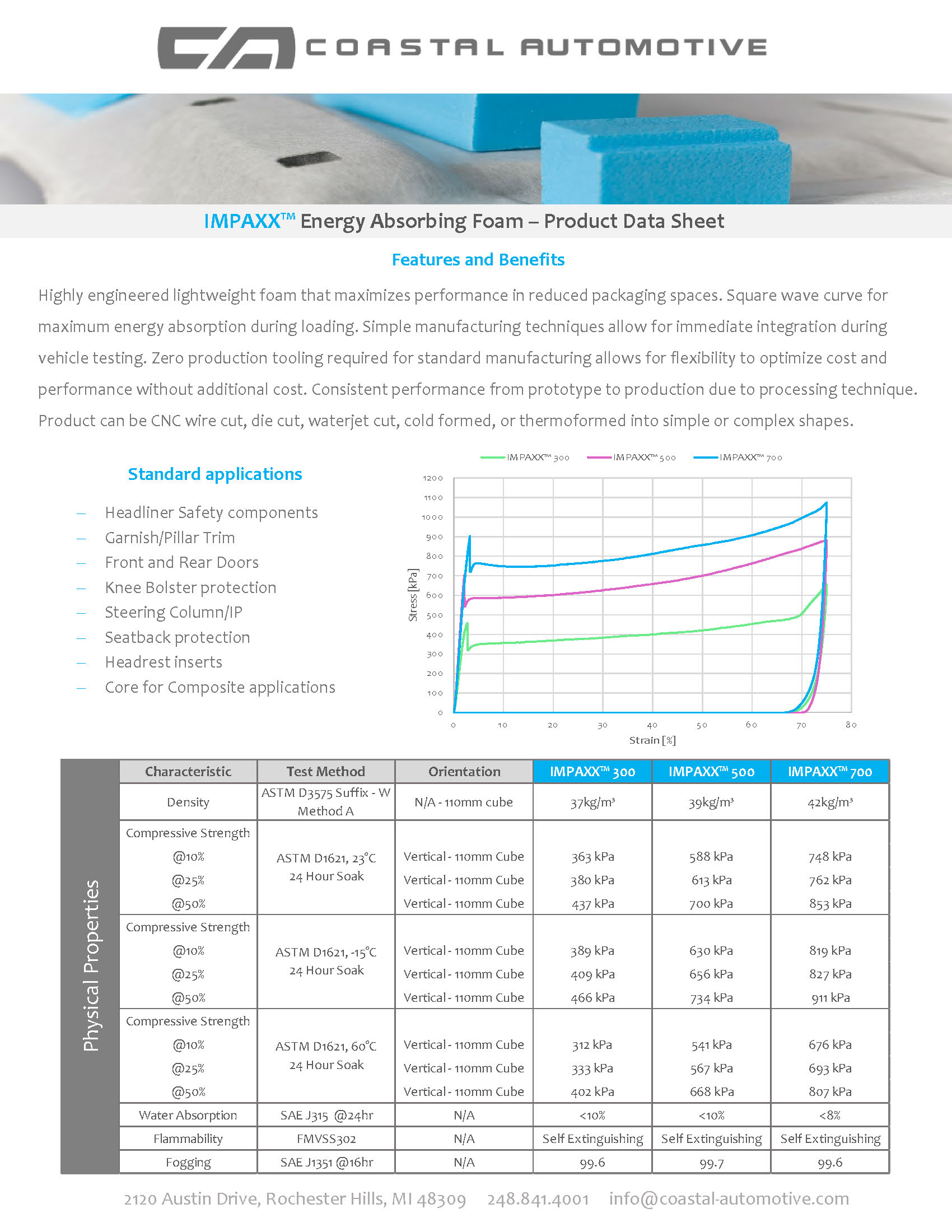

Technical Data Sheet

Download the IMPAXX™ Technical Data Sheet for details on ASTM test results, temperature performance and cutting profiles.

Energy Absorption

IMPAXX™ foam is over 90% efficient at absorbing energy, providing energy dissipation through 70% of strain. Competing materials start decreasing efficiency at 25-30% when they start to rebound, transferring the stored energy back to the occupant.

Let’s Get Started

Contact us to learn more about how IMPAXX™ might be right for your next energy-management challenge or request product samples, material cards and additional information.