This Sunday as you tune into the 105th Indianapolis 500 and watch 33 drivers complete the 500 mile race, pay attention to the entrance to pit row. On the end of the concrete barrier you’ll find what’s called an attenuator—a foam piece designed by Coastal Automotive to keep drivers safe. This attenuator has protected drivers as they enter the pit since 2017.

I Would Drive 500 Miles

Coastal Automotive began working with IndyCar after a 2015 crash during an Indianapolis 500 practice run involved driver Pippa Mann spinning off after turn four, hitting the SAFER inside barrier wall and then continuing on to hit the attenuator at the entrance to pit row. It was after this incident that IndyCar began talks with Coastal for a new foam attenuator with improved safety measures for drivers.

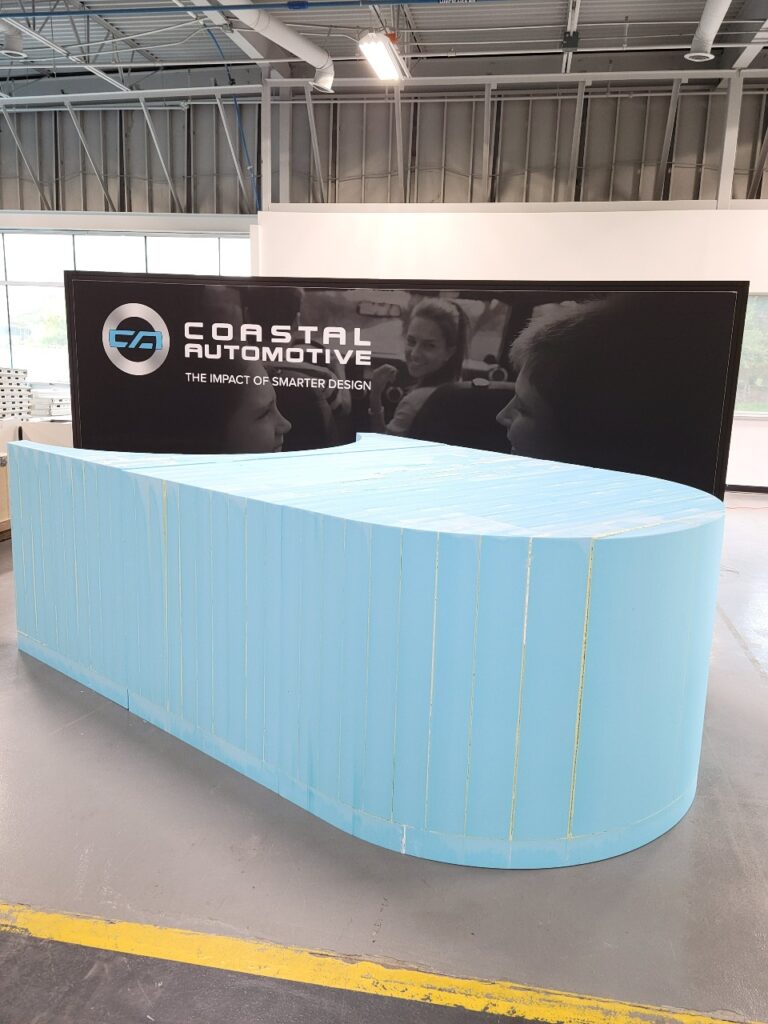

Coastal worked hard to provide an even safer alternative for drivers with the same IMPAXX™ foam used in other racing and automotive safety applications. The final attenuator stands four feet high and seven feet long, made of layers of precision-engineered lightweight foam that maximizes performance and energy absorption. Testing on the new attenuator, which is still in use today, was completed May 2017, one week prior to the Indy 500. Performance testing showed that the Coastal attenuator provided a 30% improvement in energy absorption over the previous model.

With the confirmed improvement, two parts were fabricated for the 2017 race, and the team completed the project at 8pm the Friday before the race. The very next day the Coastal team drove down, delivered and installed the new safety equipment at noon that same Saturday, 24 hours before the green flag announced the start of the race.

Coastal’s Role in Racing

This same attenuator has been in place since 2017 without any crashes or repairs. IndyCar recently ordered a second attenuator as a ready replacement in the case of an accident.

The same blue IMPAXX foam that will protect IndyCar drivers from the end of pit row also protects NASCAR drivers. NASCAR Cars of the Future all feature this foam in their car doors for improved energy absorption. IMPAXX™ was chosen over 200 different materials and found superior to the others investigated including Aluminum Honeycomb, Rigid PU, Laminates and Composites including Fiberglass Reinforcements, and Welded Steel Assemblies. This material prioritizes driver safety, lowering driver G-levels experienced on impact, all while saving on costs and minimizing added weight in the cars.

Learn more about Coastal Automotive’s forward-thinking automotive safety solutions here.