Announcing a new complementary product to support our existing line of IMPAXX™ energy management solutions.

Over the past several months, the Coastal Automotive team has been developing TereSorb™, a lightweight absorption material made entirely from recycled bottles, known as polyethylene terephthalate (PET). This innovative material excels in space-constrained applications, offering exceptional performance and passenger safety while adhering to sustainable manufacturing practices.

Protecting Passengers and Our Planet

TereSorb is made entirely from 100% recycled plastic bottles, which translates into a 50% reduction in CO2 emissions and less landfill waste during manufacturing compared to traditional rigid foam. The material also releases no CFCs or HFCs in production, which reduces pollution and promotes sustainable practices within the automotive industry.

Eco-Friendly Production

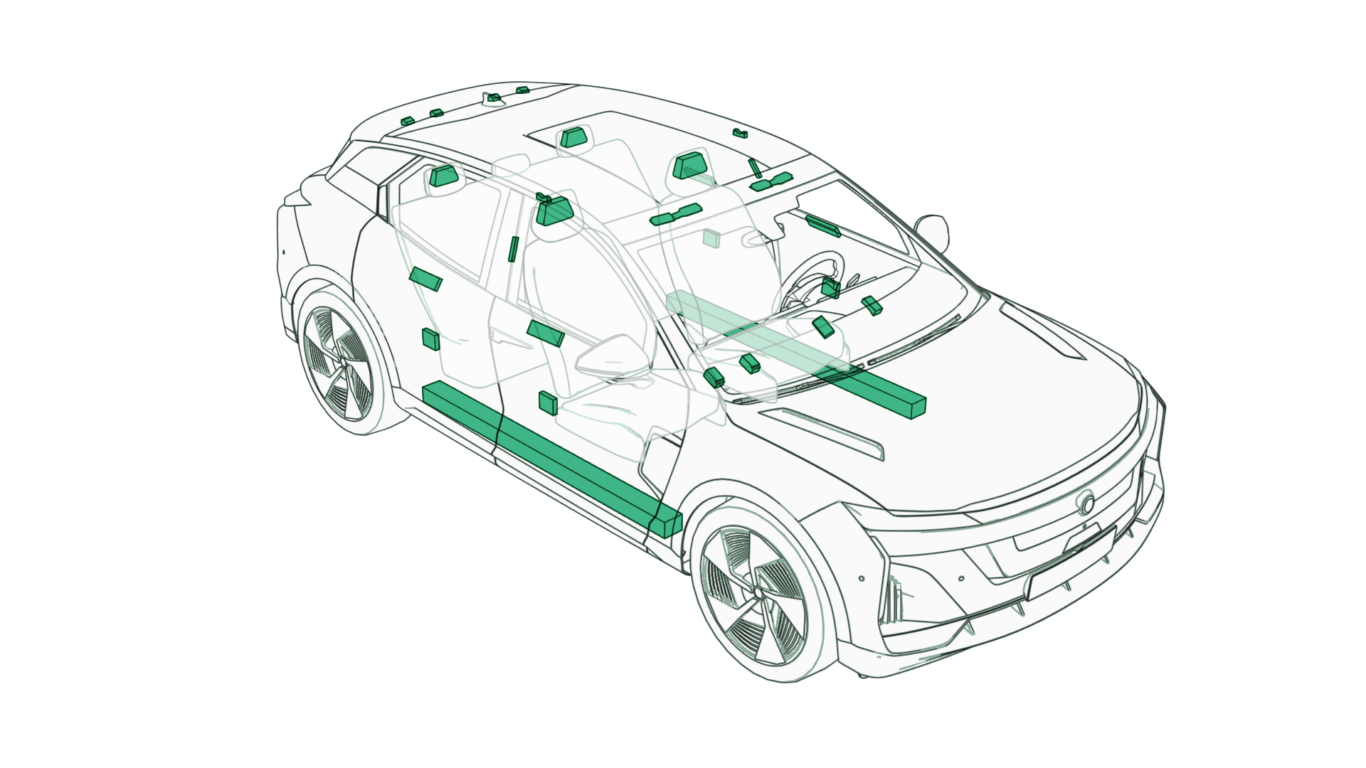

TereSorb provides rapid energy absorption and excellent thermal stability at high temperatures, making it highly effective for passenger protection. Furthermore, the material’s performance enables products to meet FMVSS 214, 201U, and 202A safety standards. Its efficient conversion techniques allow for quick development without expensive tooling, and precise CNC wire cutting ensures tight tolerances. Additionally, its lightweight design helps meet CAFE and CO2 emission standards.

Driving passenger Safety Forward

TereSorb minimizes the presence of harmful chemicals in vehicles with zero fogging and low VOC emissions. Its material properties enable innovative attachment methods, reducing the need for adhesives that contribute to emissions.

Contributing to a Circular Economy

Contributing to a circular economy, TereSorb promotes reducing waste and carbon footprints within the automotive supply chain. By helping manufacturers conserve resources and meet sustainability goals without compromising safety or performance, TereSorb supports a sustainable industry.

Complimenting the Capabilities of IMPAXX

The product is available in four grades—550, 900, 1050, and 1800—offering flexibility for applications that require a fast loading product in tight packaging spaces. Both TereSorb and IMPAXX utilize no-tooling manufacturing methods, promoting sustainability by conserving resources and minimizing plastic waste. Using these products together enables us to tailor material designs to meet specific needs, offering innovative solutions for modern automotive safety challenges.

Tailor TereSorb to Your Application

Manufacturers looking to reduce waste in their production process may consider TereSorb’s ability to transform 100% recycled water bottles into high-performance products that uphold both efficiency and safety. To learn more about TereSorb, visit our product page or contact our team.