This month Coastal Automotive began printing tourniquet clips on their 3D printer to aid the injured in Ukraine as part of Project DIAMOnD. Started in 2020, Automation Alley’s Project DIAMOnD (which stands for Distributed, Independent, Agile Manufacturing on Demand) has worked to bolster Industry 4.0 knowledge and additive manufacturing technologies to strengthen PPE supply chains using CARES Act funding.

As a member of Project DIAMOnD, Coastal Automotive applied for and was granted a Markforged emergency 3D printer to use for their own internal development and, when called upon, to provide a supply of PPE and other items in case of emergencies such as wartimes or pandemics. The centralized system of 3D printers activated this month to supply tourniquet clips for those in need of emergency medical attention in the Ukrainian war zone.

How it Works

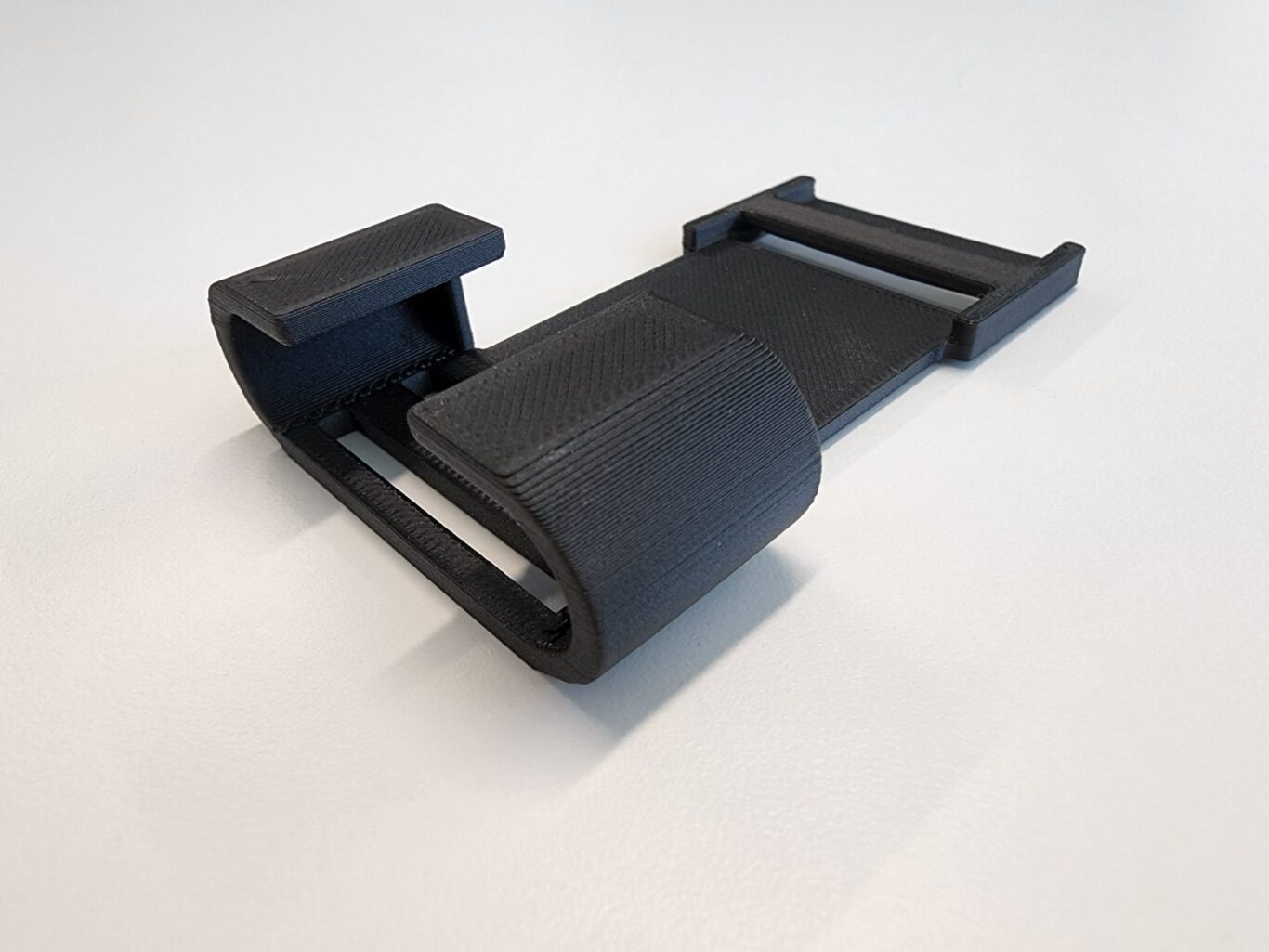

Using a roll of material reserved for emergencies, the printer utilizes a carbon fiber nylon material for printing projects on its network of 300 Michigan manufacturer printers. Finished clips will be shipped to Denmark for final assembly as part of a partnership with a Danish 3D printing organization. The parts are highly durable, as they are produced using 100% infilled product, while most 3D print applications only require around 15% infill.

The emergency 3D printer is also very user friendly, using cloud-based software to remotely upload plans for needed parts so that each end user can simply press “print” and run the machine for as long as possible each day. Due to the high infill percentage, Coastal Automotive’s machine produces approximately ten clips per day.

Industry 4.0 at Coastal

This is not the first additive manufacturing tool Coastal Automotive has utilized, as they have also used their own larger-scale 3D printer along with the Project DIAMOnD printer to create prototypes and proof of concept parts and fixtures for their machines.

“Safety is our highest priority for customers and our employees,” said Coastal Automotive President Shaun Sikora, “and we’re excited to see how additive manufacturing and other Industry 4.0 technologies continue to grow and improve safety, speed and consistency for our products.”

Mobilizing Michigan Manufacturers

“It’s wonderful to have the opportunity to be part of a tangible effort to help those in Ukraine,” said Sikora. “Giving back is a priority for us, and we’re happy to be part of a project that mobilizes Michigan manufacturers to help those around the globe.”